- YORK®

- Commercial Equipment

- Chilled Water Systems

- Water cooled Chillers

- YK Centrifugal Chiller

YK Centrifugal Chiller

250-3,000 TR (880-10,550 kW)

From schools to data centers, this water-cooled, centrifugal chiller delivers flexibility, performance and efficiency to any facility.

- Designed for maximum efficiency in the real world where 99% of the cooling season is spent in off-design conditions

- Lower installation, operating and maintenance costs

- Advanced innovations, like a variable-speed drive, falling-film evaporator and OptiView™ Control Center

Overcoming Limitations

Featured Products

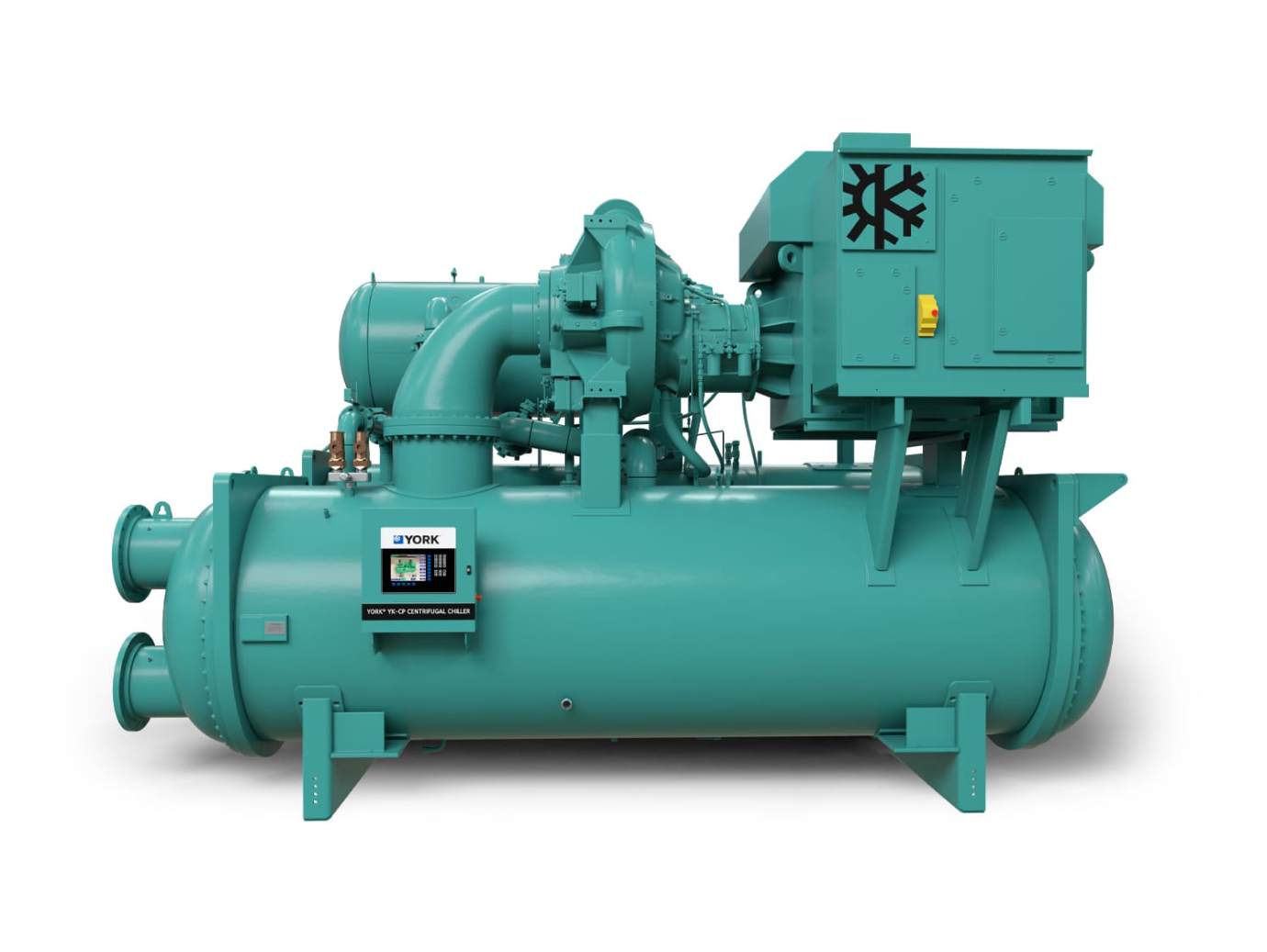

YORK® YK Centrifugal Chiller

250-3,000 TR (880-10,550 kW)

Although less than 5% of the global-warming potential (GWP) of a centrifugal chiller comes from the refrigerant it uses, we still take this contribution seriously. But simply adding a lower-GWP refrigerant to an existing chiller won’t solve the problem. The chiller will either run less efficiently or at a lower cooling capacity, or both. To solve this, the re-engineered YORK® YK chiller has been designed specifically for use with R-1234ze as the primary* refrigerant.

Additional Benefits

- Re-engineered YK chillers can be shipped from the factory with ultra-low GWP refrigerant R-1234ze or low-GWP refrigerants R-513A or R-515B, all without a size penalty.

- YK chillers are designed and tested to ensure refrigerant stays inside the chiller for reduced refrigerant emissions.

- The state-of-the-art OptiView™ Control Panel optimizes chiller performance by precisely controlling the leaving chilled liquid temperature and motor current.

- Variable-speed drive (VSD) technology can operate up to 30% more efficiently in the real world versus chillers optimized for a single, full-load efficiency.

*Also available with R-513A and R-515B refrigerants

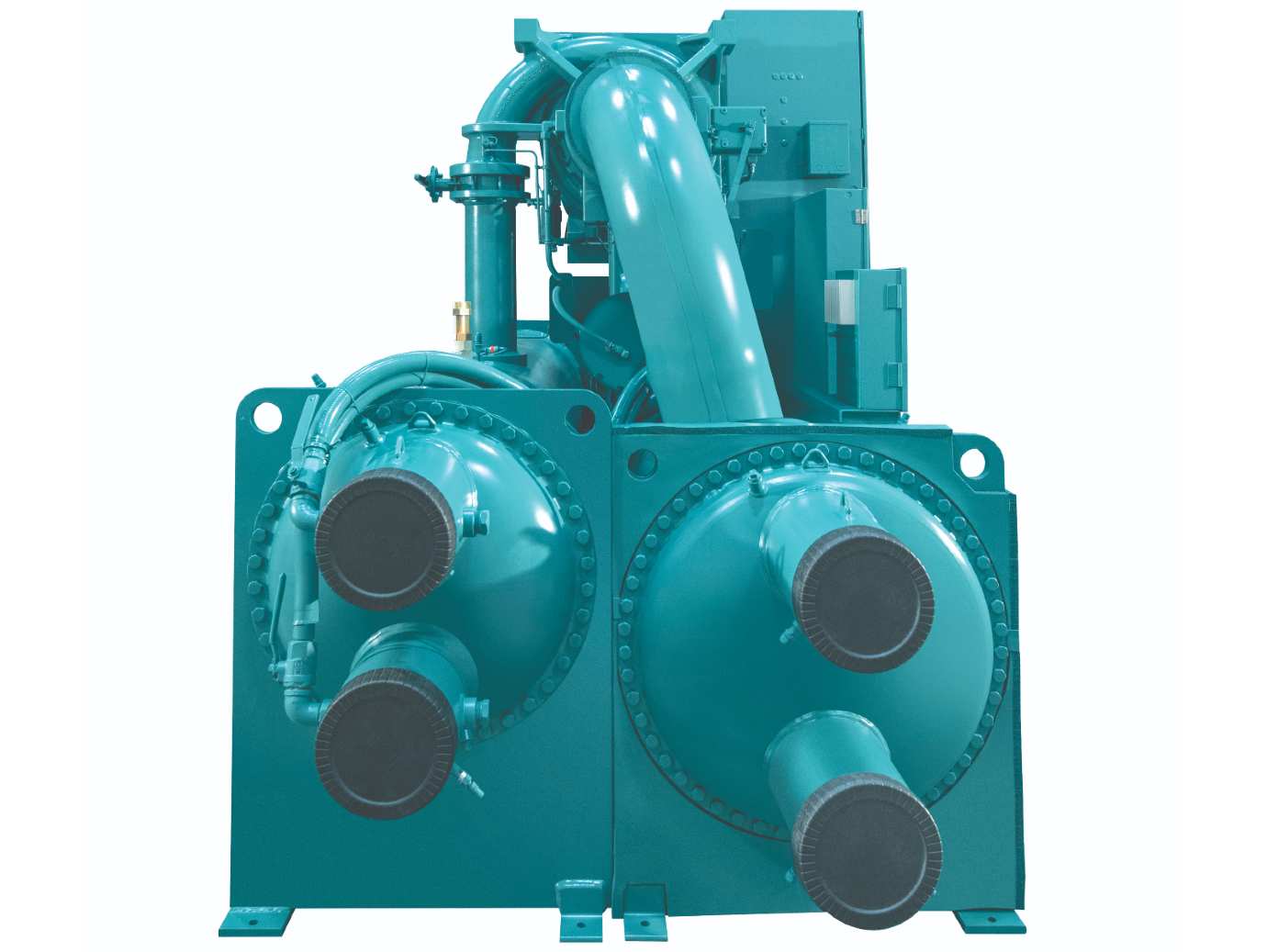

YORK® YK-CP Economized Cycle Centrifugal Chiller

2,000-3,000 TR (7,033-10,550 kW)

The YORK® YK-CP Economized Cycle Centrifugal Chiller includes all of the benefits of the YORK® YK Centrifugal Chiller while adding an efficiency-enhancing economizer and a modular configuration that allows customization for each application. From unmatched efficiency and greater application support to optimization for ultra-low GWP refrigerants and a more compact footprint, the YK-CP is the future of sustainable cooling technology.

Additional Benefits

- Newly designed economizer captures refrigerant gas during the expansion process and reinjects it back into the compressor to improve the overall efficiency of the refrigeration cycle and reduce the amount of refrigerant required.

- Modular design is more easily assembled and can be customized for specific applications, providing added flexibility and adaptability with consistent layout design across the different chillers.

- An optimized, forged converging suction line provides a streamlined refrigerant flow that minimizes losses and reduces the overall footprint of the chiller.

YORK® YK-EP Centrifugal Chiller

2,500-3,500 TR (8,800-12,300 kW)

The legacy YORK® YK-EP Centrifugal Chiller has been discontinued. Please click the link below for access to technical resources.

Benefits

Lower installation, operating and maintenance costs with system design choices that pay off in less than one year.

We engineered an unprecedented array of innovations into an integrated design that delivers superior performance with efficiencies as low as 0.20 kW/ton (17.6 COP).

We combine the highest level of application engineering support, controls software programming expertise and mechanical system experience to meet your challenges.

Features

- Designed for maximum efficiency in the face of real-world variables, where 99% of the cooling season is spent in off-design conditions

- Earn LEED® Points with credits for Energy and Atmosphere (EAc1) and for Enhanced Refrigerant Management (EAc4)

- Heat-recovery option available in units up to 2,800 TR (7,000 kW) can provide 1,200 to 40,000 MBH of heat

- Chillers equipped with the Quick Start feature can restart in as few as 25 seconds in the event of a failure after emergency power is established

- With the OptiSpeed™ Drive, energy consumption can be as low as .20 kW/TR, reducing annual energy costs by as much as 30%

- Falling-film evaporator reduces refrigerant charge up to 40%

- OptiView™ Control Center ensures optimum performance and easy operation

Johnson Controls earns world’s first ISASecure® Component Security Assurance Certification for Smart Buildings Product

- As cybersecurity threats continue to rise, the ISASecure cybersecurity program has taken a market-leading step into the smart buildings space

- ISASecure CSA certification of the YORK® YK and YZ Centrifugal Chillers exemplifies Johnson Controls leadership in bringing cyber-resilient solutions to the smart buildings market

- Certification to the ISA/IEC 62443-4-2 standard provides assurance that Johnson Controls and the YORK® brand adhere to stringent ISASecure technical security requirements for IACS components

- Certification to the ISA/IEC 62443-4-1 standard provides assurance that Johnson Controls and the YORK® brand adhere to stringent ISASecure development lifecycle requirements

More control – More protection – Better records

Learn More about YORK Chiller Access Manager

Seismic Certified

Dependable Operation With Quick Start

Heat Pump Capability

Technical Resources

Back

Next

Related Products

- With variable-speed drive, a variable-geometry diffuser and magnetic-bearing technology YORK® YZ delivers up to 35% annual energy savings versus traditional, fixed-speed, oil-bearing chillers

- Magnetic-bearing driveline offers outstanding reliability and 80% fewer moving parts than traditional oil- or refrigerant-lubricated drivelines

- Robust and reliable high-speed, hermetic induction motor reduces maintenance

- Uses R-134a refrigerant

- Economized refrigeration cycle to extend capacity and improve efficiency

- OptiView™ Control Center continuously monitors system operation

- Variable-speed driver delivers superior performance at both design and off-design conditions for higher efficiency

- Application flexibility of the chiller handles a wide range of leaving- and entering-chilled-water temperatures, fluid flows and steam conditions

- Modular configuration provides maximum flexibility, customization and compact footprint

- Two YORK® centrifugal compressors operating in parallel on a common set of heat exchanger shells

- OptiSound™ Control standard

- Full-color OptiView™ Control Center for control management at your fingertip